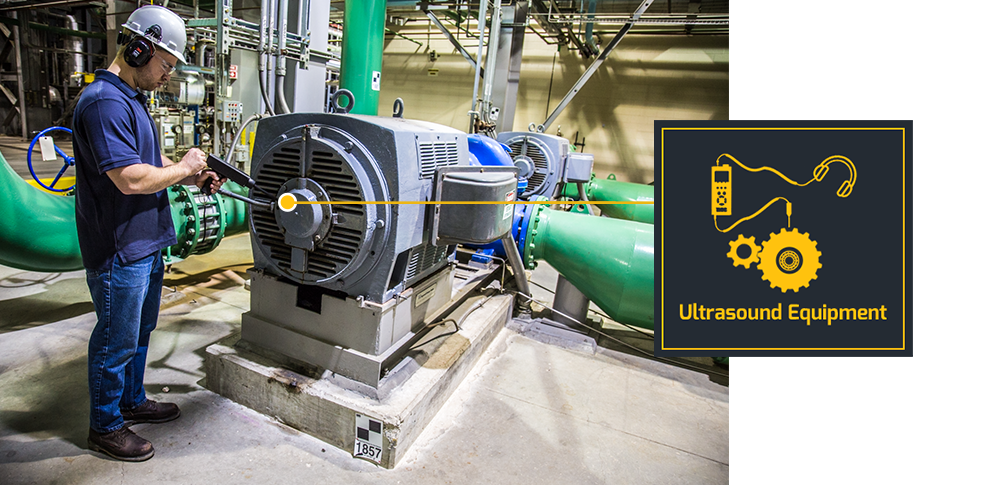

One additional piece of data which is used for rotating equipment analysis is an ultrasound listening device, this equipment was originally used extensively by the NASA space program. Although ultrasound is used as a diagnostics tool primarily for detecting air or fluid leaks, Predictive Maintenance Diagnostics uses this device to record a relative sound level at the same locations vibration data is collected. Quite often the ultrasound data is a first indicator of ball bearing degradation or when a gearbox begins to develop gearmesh problems. As with overall vibration trending, the ultrasound data trending can be very useful.

The Benefits Of Ultrasonic Bearing Inspection

Establish A Baseline Sound Level For Trending Analysis

Collecting routine data on a piece of machinery allows us to accurately identify changes in the equipment from previously recorded data

Identify An Early Stage Of Bearing Degradation

Under ideal conditions with only bearing noise being recorded, the ultrasonic noise level is a direct reflection of the condition of the bearing.

Determine A Specific Source Of Noise On A Complex Piece Of Equipment

When an audible noise is heard from a piece of equipment, it is not always easy to identify the specific source of the noise. With ultrasonic equipment, it becomes possible to pinpoint the source of the noise.