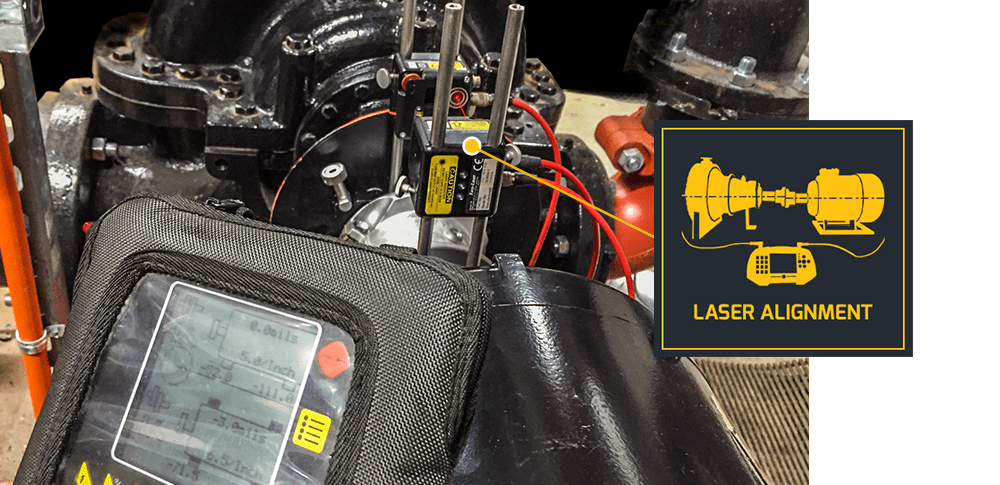

Laser alignment is used primarily to align the driven equipment to the drive equipment; i.e. pump to motor, gearbox to motor, generator to engine etc. while also assuring good drive belt alignment between two sheaves. In a direct drive application an alignment done to specifications can be effective in extending bearing life and drive coupling life while reducing excessive vibration. In the case of a belted application, laser alignment helps to improve belt wear, sheave wear as well as bearing life.

When equipment is initially commissioned into service a laser alignment, if appropriate, can be used to be certain there is minimal stress on the couplings while also minimizing excessive loading on equipment bearings. A byproduct of good alignment is reduced vibration levels on the equipment.